Drones in the Warehouse of the Future

March 8, 2020 – 10 minute read

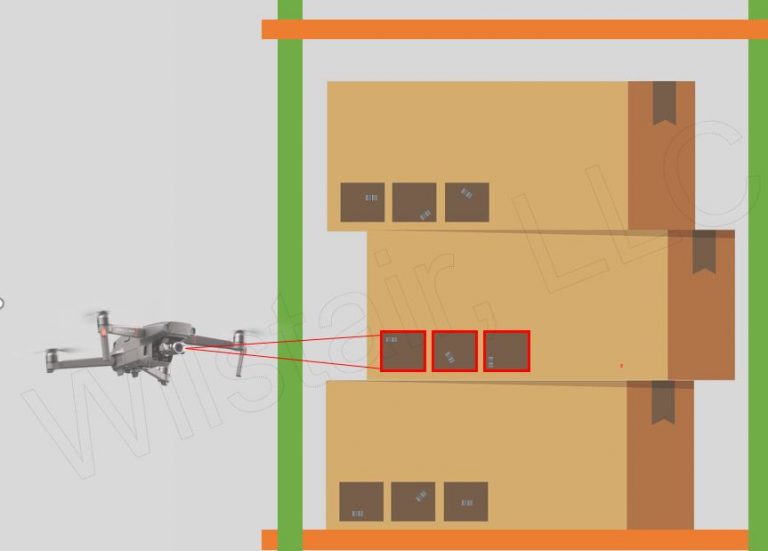

As logistics companies continue to chase after the ever growing consumer demand for real time order fulfillment, inventory management is an extremely important piece of data to ensure that the adequate inventory is ready and available to meet such demands. Counting inventory inside large warehouses is nothing new to the industry, and there are a number of tools to accomplish the task; however, the human factor remains an opportunity in the accuracy of the counts along with the labor time investments made on a weekly basis to count the inventory of an entire warehouse. Although, humans will not be completely removed from the process in a near future, a new tool will enable warehouses to transform the methodology for how inventory is counted, in the form of a drone, Figure 1.

Figure 1: Drones Scanning Inventory in a Warehouse

Let’s get started and address 10 important questions to understand if drones are the right tool for your warehouse or distribution center (DC):

- What is a “drone in a warehouse?”

- It is a fully or semi-autonomous robot capable of flying in between aisles and inside confined warehousing or DC facilities. The drones themselves can scan all barcodes and tags of front facing pallets, case stock boxes, or bulk storage along an aisle. The key to this tool is not its ability to fly, but rather its ability to read and collect the data in short flight cycles with little to no human intervention.

- Who are the end users of drones in a warehouse?

- Operations, innovation, continuous improvement managers, data analysts, or those individuals that carry the responsibility for taking several hours during their work week to perform inventory counting tasks in addition to their many other duties. Also, this a perfect tool for those in operational optimization, and efficiency management roles. Primarily, organizations with seasonal, bulk, or extensive inventory along with third party logistics (3PL) seeking to position themselves as trusted entities for their customers are among some of the key stakeholders that are subject to benefit from the technology.

- Can they be used at any warehouse and distribution center?

- Unfortunately, the answer is that “it depends.” If you have a facility of less than 100,000 sq.ft., then a manually flown drone that uses your existing scanners and feeds the data onto your established warehouse management system (WMS) can be a good secondary backup option to your existing tools and methods while keeping the initial investment low. On the other hand, if your facility is greater than 100,000 sq.ft., then fully autonomous drones should be highly considered.

- How much does it cost?

- Well, here is where the “it depends” factor differs between facility layouts and operating structures of a company. Without delving into the technical aspects of the systems, too smart and complex of a system means that your integration cost will greatly offset the investment of the technology. In other words, if you are looking for a highly complex system and there is no operational flexibility from your company, be ready to make some significant investments. On the other hand, if you have some operational flexibility, the installation of a fully autonomous system can be more affordable than you think, and can yield operational savings within 9 months or less.

- What does the drone do when it flies inside the aisles?

- Besides flying on its own in confined spaces within your warehouse without the need for a pilot, the drone can read your existing inventory barcodes and feed its findings and data into the WMS.

- What are the benefits of using drones in a warehouse?

- Inventory data accuracy. The drones not only can scan and read the barcodes, but can also feed, read, and compare such data against existing WMS inventory data. As a matter of fact, they can immediately tell you of any discrepancies during the counts that allow inventory managers to quickly pinpoint the source of mis-matched inventory data. Site personnel can quickly investigate what is the source of the problem by viewing the image(s) taken by the drone during the scan without the need of sending someone out on a lift to physically look at the pallet or boxes. Another benefit is the reduced times that it takes to perform a complete scan in the facility. For example, if today your team requires 60 days to scan all inventory, tomorrow with the use of autonomous drones, the task can be accomplished in half of the time or less.

- What about safety?

- Although these drones are smart, they are not yet recommended to operate in areas where there is foot traffic. Granted, there are technology methods for dynamic obstacle avoidance, but if desired, then here is where the solution can offset the investments made in the tool.

- Are companies using them today?

- The technology is still maturing, but it has come a long way in the last couple of years. Majority of the companies using and investing in the technology today understand the benefits that it delivers but are also evaluating how much flexibility they are willing to commit within their operational models and facility layouts. Again, back to ROI, the smarter the robot is, the more costly and complex the system will be, so there is always a sweet spot to the adoption of using drones in the warehouse.

- Why are companies investing in adopting drones as a tool for the warehouse?

- Simple. Consumer demand and competition. The more data and control over the inventory that a company has, the more opportunities there are for landing a contract or expanding the scope of new customer acquisition. For example, a clothing or textile company would be far more willing to invest in a 3PL that can supply continuous inventory digital data and at high inventory accuracy percentages, over a competitive company that may also supply a high percentage number, but with a scanned batch of hand written sheets. For those companies investing in this technology, it is all about positioning themselves as thought leaders now in the best interest of their clients or customers. In the end, it all translates into more data, more control, more information, happy customers.

- Will the drone and a single battery take care of my entire facility?

- At the moment, the answer is no. In most cases, end users will require multiple drones and several batteries. The good news is that the drones not only navigate on their own, but can recharge themselves without any human intervention. The drone take off from its starting location, which may vary depending on which aisle needs to be scanned, and when it is low on battery, the drone simply returns to a charging location to recharge. While one drone is recharging, another is continuing the job. As for how many drones and batteries, the driving factor will be the size of your facility, your operational structure, and your required inventory count schedule.

Now that you have a better understanding about how drones can be a great tool for your warehouse, your next step is trying it out, and Wilstair is here to help you. Our company has been in business for nearly five years with a core focus of using drones for inventory management and logistics in the United States. We have seen and done it all, from building manual custom drones with on-board scanners to integrating highly sophisticated autonomous systems inside the warehouse. Wilstair works with some of the best companies and partners in the industry and we are here to help your warehouse or DC integrate the best drone solution for your business. Email us at contact@wilstair.com, or submit an inquiry through our website.